Nest quickly or think through for maximum efficiency>

NESPERT CAM - base of the NESPERT systems for nesting and NC programming of sheet parts processing:

True shape nesting Excellence

Improve your nesting process with NESPERT CAM. Even with the best systems on the market, nesting complexities can be a pain point. Our solution provides automatic and interactive tools applicable to any type of thermal cutting.

- Integration of preparation, planning and true shape nesting.

- CAD integration and automatic geometry correction.

- Pricing and quoting both on jobs and orders.

- Enhanced nesting opportunities with higher quality and fewer defects.

- Application of technology according to machine, energy source, material, type of processing,

- Fast transfer of layouts and NC programs from one machine to another machine/technology.

- Efficient reuse of remnants and simplified unloading.

- Work in native, 64-bit mode on Windows and Linux.

NESPERT performs automatic and interactive nesting with: Optimisation and tight step-by-step nesting, with unlimited part-in-part nesting of parts in holes and on-line control against overlapping.

The nesting algorithms in NESPERT have no limitation of accuracy and dimensions. Even 15 years ago Vintech RCAM was nesting with or without technology on plates the size of ½ football field and was programming processing with an accuracy of 0.001mm.

NESPERT nests whole plates and usable remnants,

NESPERT applies automatic and interactive processing technology with on-line control against overlapping, allows to create, edit or remove the processing technology in the whole layout or for a part of it at any time.

The user interface is based on visual management of project, plates, parts, nesting layouts, nesting and technology.

NESPERT imports parts from CAD files in the formats DXF, DWG*, SVG, ESSI, DSTV-NC1, CDW*, FRW*, PSM*, NX Ship XML with automatic correction of geometric defects.

The input CAD geometry can contain arcs, segments, ellipses, splines, point sets and text. The import performs an automatic analysis of the contours of a part, such as outer, inner, slots, marking.

Libraries with parametric shapes have been developed in the system, allowing the creation of part geometry by entering dimensions.

Geometry import is possible in various ways, through: file selection, multi-part import, batch import by nesting specification, import from AutoCAD blocks, import through on_line interface with CAD systems SolidEDGE, KOMPAS-3D and off_line interface with Rhino CAD.

The processing of sheet parts of different materials and thicknesses using different energy sources requires the application of special software solutions.

NESPERT CAM has fully functional and advanced automatic and interactive functions for processing technology management, such as different types of common cuts, common cut snap of parts nested on a nesting layout, common cuts with spikes, fly cutting, processing to material, avoiding collisions with circumventing, chain-cutting, cutting with bridges and gaps, slicing the scrap skeleton, L-locks and eyelets for cutting thick-walled parts, parallel torches with variable number and step, processing with regular or irregular frames, creating a nesting layout only with chain-cutting, NESPERT CAM features the unique technology for post-marking by program of the plate heat № on parts in the Nesting layout with automatic reprogramming.

The first implementation of bevel cutting with Vintech RCAM was in 2006.

Since then, the technological capabilities of the system have been continuously developed and today, the optional NESPERT rBevel module for bevel cutting technology is one of its iconic features.

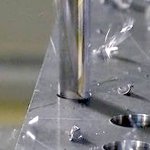

The development of the optional NESPERT rDrill module for programming complex drilling, threading, boring and milling operations began in 2010.

Today, true shape nesting and programming of a CNC thermal cutting machine combined with a vertical machining center is performed with the maximum degree of automation and with unique interactive capabilities.

When several thermal cutting machines are operating in the workshop, they rarely are from the same manufacturer and programmed with the same CAM system. Using multiple CAM systems for true shape nesting in the enterprice leads to higher training costs and less flexibility in production.

NESPERT CAM has advanced capabilities for nesting and programming various CNC machines from a single workstation.

All settings and cutting regimes in the system are supported by machine in an open and editable Technological Datasets Base. The user has full capabilities to set the results from the performance of the system according to their needs.

The datasets and settings are supported in a local or network SQL database.

Open Postprocessors are used to generate NC programs.

Pricing and offering is based on editable datasets with labor and material estimates.

Documents are generated using editable document templates.

Using a single NESPERT CAM system for all CNC machines for true shape nesting preserves accumulated professional experience and competence without disrupting the established business processes.

NESPERT - general view

NESPERT - technology at any time

Nesting preparation

NESPERT CAM provides solutions to the task of "Optimal nesting of parts on a plate and programming the machine for cutting the parts".

The nesting preparation includes a set of tasks, which: Define the parts, Price the orders, Select the plates, Track the progress of the production preparation, Save the orders after changes by the customer.

NESPERT organizes the work on cutting orders with the CAPP (Computer-Aided Process Planning) system NESPERT Manager, NESPERT Warehouse SM – for controlling metal inventory, and the NESPERT rSales library for quoting and pricing.

NESPERT CAM and NESPERT Manager generate cost documents, offers or proforma invoices using the information from Nesting Layouts, a Project or a Nesting Order. NESPERT allows the use of different pricing methodologies:

- Preliminary pricing after import of parts, without nesting,

- Preliminary pricing after import of parts, with automatic nesting by order,

- Precise pricing after nesting based on Nesting layouts and NC programs.

NESPERT Warehouse SM supports information about warehouse logistics of whole plates – plates on the way, in storage cells and on machines, and for usable remnants in storage cells and on machines. The system supports full information about deliveries, warehouse movements, dispatching and exhausting sheet materials.

NESPERT Warehouse SM „knows“ the weight, grade, thickness, shape geometry and the history of changes of each plate until it is exhausted.

When NESPERT CAM and NESPERT Warehouse SM operate under NESPERT MES, the plates and usable remnants in the nesting project are selected from those available in the warehouse or, if there is no stock – from plates for delivery.

NESPERT Warehouse SM supports the reservations of the plates confirmed for production. It “returns” the usable remnants calculated after cutting in the warehouse in a cell near the machine.

The nesting order preparation in NESPERT Manager starts with importing parts, preliminary nesting, pricing and offering.

The integration of NESPERT Manager and NESPERT CAM allows automatic reporting of the status of each part in the order: Geometry ready, Planned for production, Added in nesting job on a machine, Nested on nesting layouts, Programmed in NC programs.

For maximum filling of each plate, NESPERT can mix parts from different nesting orders.

NESPERT's integrated work environment allows in real time to:

- Determine the material consumption by orders,

- create a production schedule according to Nesting layouts/NC programs,

- control the condition of each part during the nesting preparation,

- help the distribution of the parts after cutting from the nesting layout.

Nesting production management

The subject of management for a true shape nesting production system includes Orders with sheet details, CNC machines, Sheets, and Usable Remnants. A key element is Qualified Personnel.

To manage this system, Vintech created NESPERT ViNES, which integrates NESPERT CAM for true shape nesting and NC programming, and the CAPP (Computer-Aided Process Planning) system for production preparation and planning, NESPERT Manager.

NESPERT Manager plans production with true shape nesting based on orders and/or stages, and the machines produce parts based on Nesting layouts.

The different subject matter of planning and production complicates the tasks for: Tracking the production status for parts from orders, Production progress data collection, Warehous and workshop logistics, Machine load balancing, Workshop and production change management.

NESPERT Manager is a fully functional solution to these tasks.

New innovative solutions are being developed in CNC true shape cutting machines, and companies are developing their production capabilities by implementing new machines.

New machines come complete with a CAM system, which is generally different from the ones currently used in the enterprise. Working with many CAM systems is an issue of efficiency and productivity.

NESPERT CAM successfully replaces the "original CAM system" on a new machine in the enterprise. A Technological Datasets Base and Postprocessor are set up.

As a result, the accumulated professional experience and competence is successfully preserved without disrupting established business processes.

Meeting order deadlines requires continuous control of nesting layouts completion times. When a CNC machine enters a repair state, the execution of the schedule for some orders is jeopardized. Often, when working with many machines in the workshop, one CNC machine is underloaded and another is overloaded.

When delays become a problem, Nesting layouts need to be moved from one machine's schedule to another machine's schedule.

We call this process load balancing on thermal cutting machines.

When the machines are similar, for example between two machines from the same manufacturer with the same processing technology, moving nesting layouts does not require work with a CAM system. NESPERT Production supports such machines as a group where the Nesting layouts are placed in a common queue.

The thermal cutting machines in the workshop usually differ in power source, CNC control, degree of automation, etc. In general, moving with a change in thermal cutting technology requires working with a CAM system. There are several scenarios:

- Nesting and reprogramming with CAM system - from scratch to NC program. This is the slowest way. A bad scenario is when different machines are programmed with different CAM systems. Using NESPERT CAM precludes this relocation scenario.

- In a CAM system, for each nesting layout, NC programs are generated for all machines that can perform the processing. The processing is performed using one of the NC programs and the others are stored as spares. This is the fastest transfer method applicable to machines with the same type of processing.

NESPERT CAM has the capability for transferring using this scenario, but it is not recommended.

- NESPERT CAM opens the nesting project in which nesting layouts have been created. Using transfer functions automatically changes the material, machine, carriage/power source, cutting regime, kerf and post-processor for a nesting project or for an individual Nesting layout. When there are paths with a common cut in a nesting layout, it is preserved if the kerf does not change.

This change method is the most effective.

The true shape nesting production management system NESPERT ViNES enforces strict control of sheet metal in the workshop and warehouse.

Each plate in NESPERT Warehouse SM has a unique identifier, through which its depletion history is tracked. For enterprises that are obliged to provide traceability by heat №, this is the basis for guaranteeing the quality of the produced parts.

A mechanism for replacing a plate, immediately before processing, while preserving the quality of the sheet has been developed in NESPERT Warehouse SM.

As a result, the time for workshop logistics is significantly reduced.

The information from NESPERT ViNES reaches each CNC thermal cutting machine through a NESPERT Operator console. The machine operator registers with a chip card at the console.

A queue of Nesting layouts is supported on the console. The operator has all the necessary information for the job, including the ability to verify the NC program.

The nesting layouts that are complete with plates can be in the following states: Released for Production, Suspended, Aborted, Partially Completed, and Completed.

When the CNC machine has remote NC program loading functionality, the Run to Production function of NESPERT Operator loads it for execution. For machines that do not have this functionality, the operator selects and loads the NC program by name.

The reporting of the execution of the Nesting layout allows NESPERT Production to monitor the progress of the execution of cnesting orders in the workshop, the produced parts and the time according to the program for their production in the account of each operator.

NESPERT ViNES scheme

Download Demo NESPERT CAM

DEMO version of NESPERT CAM for getting acquainted and trained.

For Windows (64-bit) 10,11; License: Freeware

Language: Interface and Help - EN, BG